More than a technical office, it is offering you customised solutions for your system.

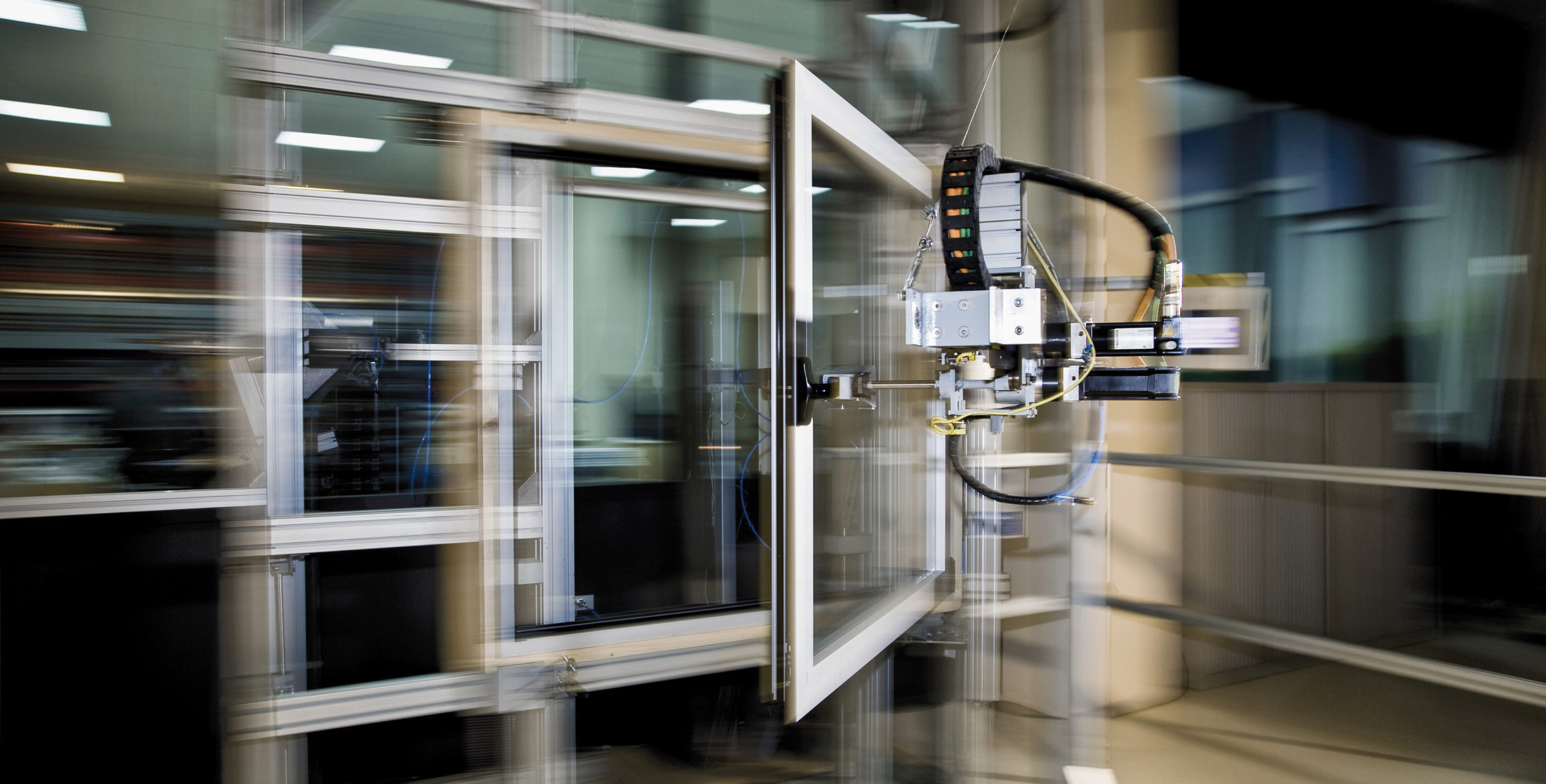

At STAC, we have a comprehensive technical office to find the solutions you need to make your closing systems better and more efficient.

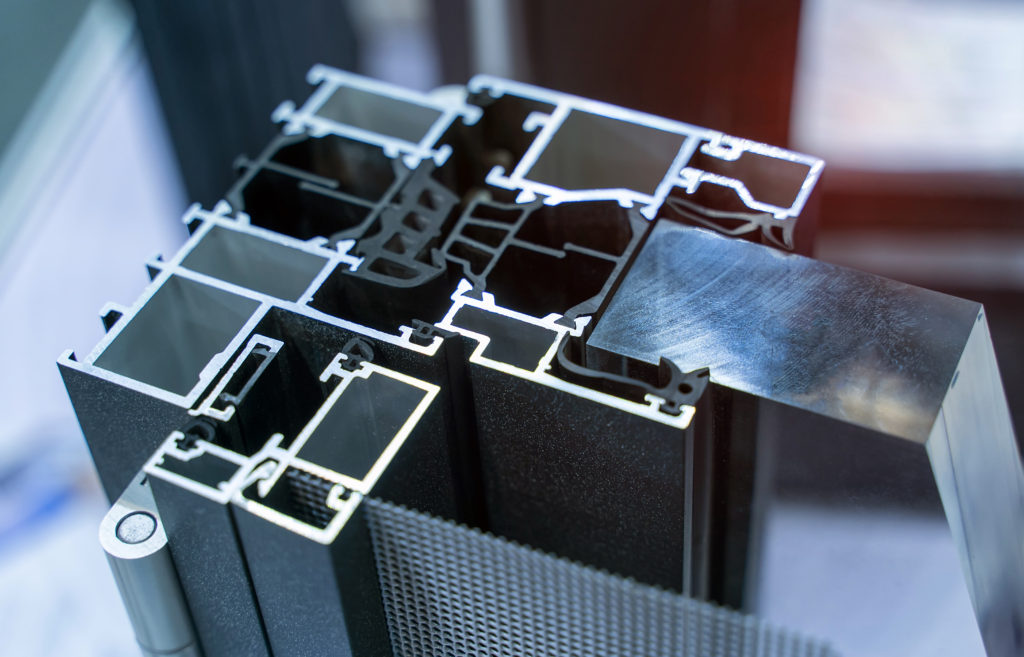

We consider the closing systems of doors and windows as a whole, allowing us to offer you a differentiated solution.

We design products especially for you in all product lines, integrating everything to perfection.

Thanks to our extensive experience, we can advise you on the materials that are best suited to your system.

For us, a project does not end once our products have been installed, that’s why we offer the best after-sales service.

Thanks to our 20 years of experience designing and manufacturing hardware and accessories for aluminium systems, we can offer you the most cutting-edge solutions, especially designed to meet your needs.

With this aim in mind, we have an in-house technical office at our factory, to ensure 100% control over the whole process.

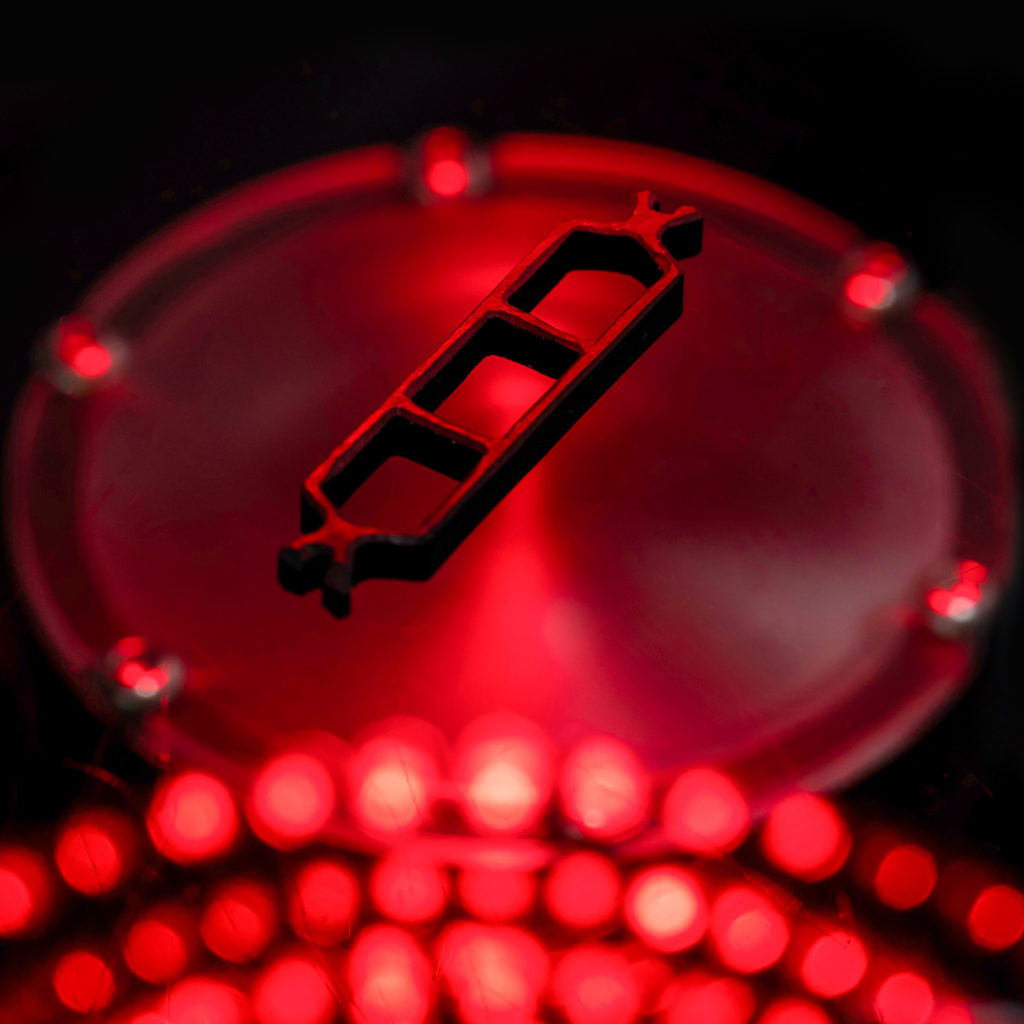

Our expert thermal break team works by your side to offer you the polyamide and ABS profiles that you need to improve the energy efficiency of your system.

The core value of our technical office is to achieve the perfect profile so that you don’t have to worry about a thing.

STAC was founded as a company specialised in sealing gaskets. Today, we place all our expertise at your service to offer you the gasket solutions that you need.

Our technical office will advise you at all stages of the process, from the design to the materials, providing you with the best comprehensive solution.